Problem: During mining operations in an open-cut mine, there has been an increase in reversing incidents between several D10 dozers. In one incident, an operator reversed at speed into the side of another dozer. Not only did this cause considerable damage to both pieces of machinery, the significant costs involved with loss of production had run into the hundreds of thousands of dollars.

Solution: APS was approached and tasked with implementing a solution to this issue. APS proposed the install of a heavy-duty close proximity radar system to alert operators of objects or machines in there blind spot. APS was involved throughout the entire process; from system configuration and installation; to training of the operators to ensure competency, operation and maintenance of the radar system.

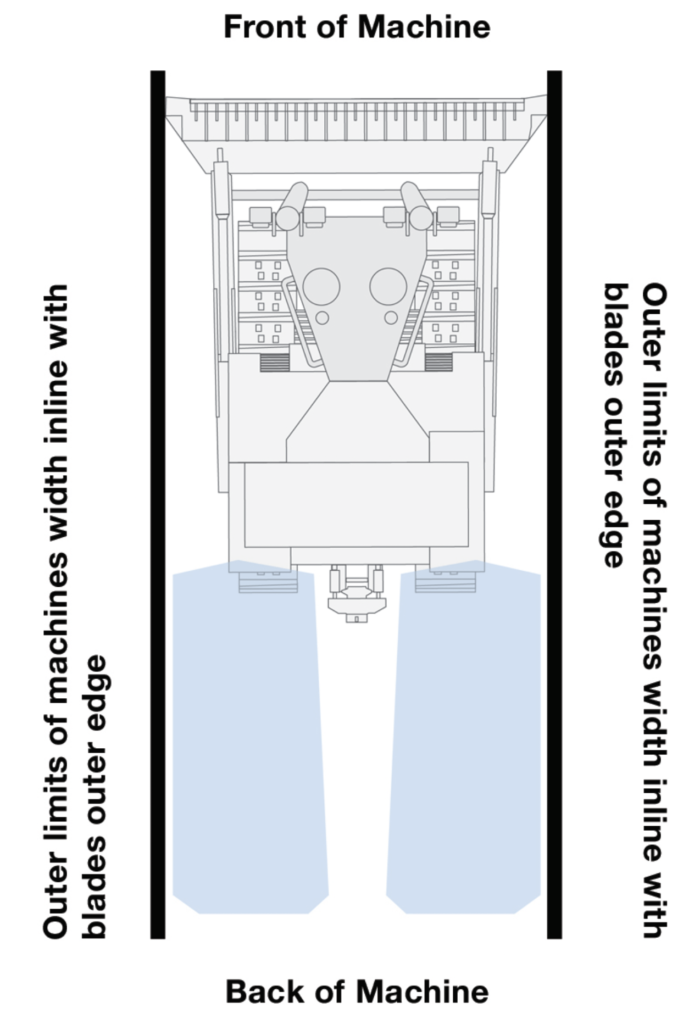

The system consisted of 2 x LED displays mounted inside the cab to provide the operator with independent left and right visual and audible alerts via each display, 2 x Preview Sentry radars were installed on the rear LHS and RHS corners of the dozer. The sensors were configured to a detection area of 6m in length and 2m in width, it was critical that the radar detection zone did not protrude past the outer left and right edge of the dozer blade. This was to ensure when the operator tracks come into close to stationary objects such as high walls, stockpiles and wind rows, the radar does not alert and create the potential for false detections.

The system consisted of 2 x LED displays mounted inside the cab to provide the operator with independent left and right visual and audible alerts via each display, 2 x Preview Sentry radars were installed on the rear LHS and RHS corners of the dozer. The sensors were configured to a detection area of 6m in length and 2m in width, it was critical that the radar detection zone did not protrude past the outer left and right edge of the dozer blade. This was to ensure when the operator tracks come into close to stationary objects such as high walls, stockpiles and wind rows, the radar does not alert and create the potential for false detections.

Goal: The goal was to achieve a safer and more productive work environment for the operators of the dozer fleet, and to help prevent further collisions from occurring. The solution has been a success and near misses and incidents have been minimized to near zero. APS has also completed training with the dozer operators, and feedback from management and everyone involved agree “the system has created a safer work environment for all operators and staff”.

Contact your local APS representative to discuss how we can tailor a solution to meet your needs.